Dry tower

Dry tower

This is where liquid raw dairy materials are dried and turned into semi-finished products which are then converted into high-quality calf milk powder by the various calf milk manufacturers.

Top-quality calf milk begins with top-quality raw materials. Low-fat milk powder and whey powder are the key ingredients.

When it comes to whey, there is a difference between sweet and sour whey. Sour whey is a by-product of yoghurt manufacture, whereas sweet whey is obtained from the cheese-making process.

Taking samples & Laboratory

Taking samples

The delivery driver parks his truck next to one of the silos, ready to unload his consignment of low-fat milk or whey. Before any raw materials are allowed to be unloaded from the truck, a sample first needs to be taken.

All raw materials supplied to the production company have to meet strict standards. The core values are ‘safe’ and ‘clean’. Only when the laboratory has given the green light can the driver start unloading the consignment. The raw materials then enter a closed production system. This ensures that only pre-approved substances can be used in making the calf milk, and hence guarantees a safe final product with a consistently high quality.

Laboratory

A company employee runs off some of the liquid into a bucket. He then takes the bucket to the laboratory where the quality of its contents is tested. The driver is not allowed to unload the rest of the raw materials from the truck until the sample has been given the all clear.

Sample

The quality of the sample is tested.

Unloading station

Once the laboratory has given the all clear, an automated system opens up the pipeline and empties the tank truck. A complex system of pipes ensures that the truck’s consignment of raw materials ends up in the relevant silo. Each delivery is always stored in a separate location.

Production area

A computer-controlled system ensures that the warm liquids flow into the relevant pipes so that the water can be removed, leaving behind a high-quality powder. This produces various different types of powder which are semi-finished products for use in the manufacture of calf milk powder.

Powder

This produces various different types of powder which are semi-finished products for use in the manufacture of calf milk powder.

Formulation room

Formulation room

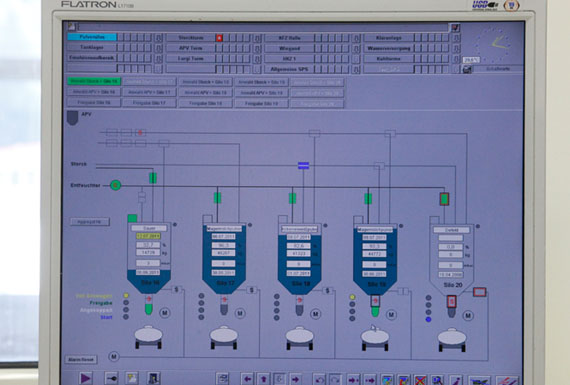

Employees in the formulation room determine which warm liquids they are going to dry next. Using an advanced computer system, they control which silos will release some of their contents into the production process. After the liquids have been heated to remove the water and the resulting powder has been dried, the product is then ready for further processing.

Computer

De computer legt vast wat in welke silo zit. Medewerkers in de receptenkamer kunnen zo gericht de grondstof afroepen.

Loading for transport

Tank trucks extract the powders from the storage silos and transport them to calf milk manufacturers.

A tank truck only ever carries one kind of powder. In this way, the powder manufacturer receives all the raw materials separately and can mix them as required in line with the relevant formulation.

This is how the drying tower and calf milk powder manufacturers contribute towards producing veal safely and responsibly.

This is the end of the tour dy tower. Choose another link in the chain or use the red arrow on the right to navigate back to the floor plan.