Feed production

Delivery & taking samples

Samples

At the calf milk producer, the delivery truck drives into the sampling area. The driver opens the valves on top of the tank so that a member of staff can take samples. Using a long hose, powder is extracted from within the tank at several different heights. The samples are then mixed and taken to the laboratory for testing.

The tank truck can leave the sampling area, but has to wait until the samples are given the all clear before the powder can be unloaded. An automated system then opens up the pipeline and empties the tank truck.

Taking samples

Laboratory

The laboratory plays a key role in terms of food safety. This is where staff test all the raw materials used in producing calf milk. Only once the consignment has been tested and approved is the truck driver allowed to unload his delivery.

In addition to stringently testing the raw materials, the laboratory also examines the end product, veal. This has to be 100% approved in order to be safe to eat.

Samples

All samples receive a unique code in order to keep records straight. The laboratory has a large storeroom full of samples of raw materials and final products, since all samples need to be kept for 9 months. If it should emerge that there is a problem with the feed within that timeframe, the cause of the problem is usually soon identified. If necessary, another independent laboratory will subject the stored sample material to counter-analysis.

When it comes to food safety, the veal sector leaves nothing to chance.

Tests

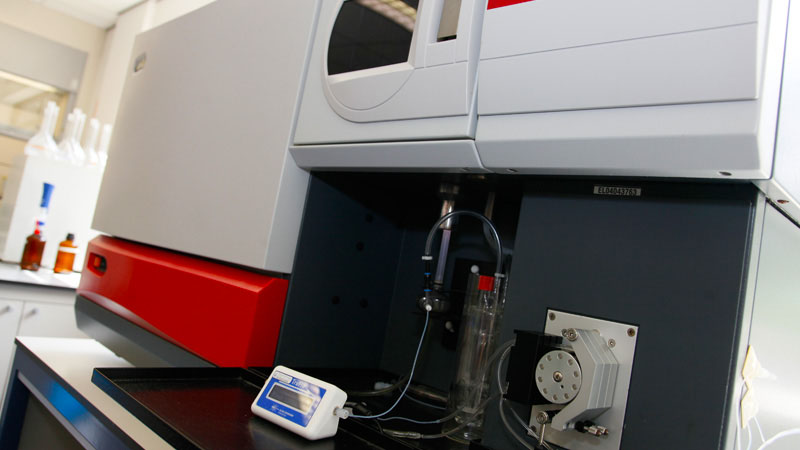

The laboratories use state-of-the-art testing equipment. This device measures the mineral levels in the feed. Minerals are substances such as iron, zinc, copper, magnesium and potassium, all of which are nutrients a calf needs in order to grow.

The laboratories also assess the quality of the roughage that the calves are fed in addition to calf milk. And they monitor the quality of the animals’ drinking water.

High-grade and reliable feed is not only important for the animals’ welfare, but also for food safety.

Delivery of raw materials & pipes

Delivery of raw materials

Top-quality calf milk begins with top-quality raw materials. Low-fat milk powder and whey powder are the key ingredients.

All raw materials supplied to the production company have to meet strict standards. The core values are ‘safe’ and ‘clean’.

When a truck arrives to deliver raw materials, its consignment is first subjected to sampling. Only when the laboratory has given the green light can the driver start unloading the consignment. The raw materials then enter a closed production system. This ensures that only pre-approved substances can be used in making the calf milk, and hence guarantees a safe final product with a consistently high quality.

Pipes

A complex system of pipes ensures that the truck’s consignment of raw materials ends up in the relevant silo. Each delivery is stored in a separate location, and the computer system registers what is being held where. Staff in the recipe room can then call off precisely the raw materials they need to produce a particular type of calf milk. Computer-controlled mixers ensure that the final product is made in exact accordance with the relevant recipe to guarantee a consistent quality.

Production area

Production area departement 4

The production process runs literally vertically – 16 metres from the top to the bottom.

Staff in the formulation room determine how much powder they need from each silo. A complex system of pipes feeds the different types of powder into the mixing machine. There, the resulting mixture falls 8 metres downwards. A kind of fan blows air upwards into the machine to ensure that the powder granules drift down slowly. Warm fat is sprayed from the sides and in effect encases the powder granules as they fall. This results in calf milk powder that has all the right ingredients to help the animals grow strong and keep them in top condition.

Production area department 3

This unit sprays warm fat into the mixing machine. The large number of pipes and the tiny outlets create a kind of fatty mist in the mixer. It is very important that the powder granules are coated with precisely the right amount of fat – not too much and not too little. To monitor the quality of the final product, the calf milk, formulation room staff take a sample every half hour and the sample is then analysed in the laboratory.

Calf milk manufacturers do their utmost to ensure they supply nutritionally balanced and responsible feed to their customers. This not only keeps the calves in optimum condition, but also contributes to consumer food safety.

Production area department 2

The mixing machine is 16 metres high and accessible at several levels, making it easier not only for maintenance purposes but also for taking samples. Samples can be taken at a number of different heights, and hence at each individual stage of the manufacturing process.

Production area department 1

The mixing machine is 16 metres high and accessible at several levels, making it easier not only for maintenance purposes but also for taking samples. Samples can be taken at a number of different heights, and hence at each individual stage of the manufacturing process.

Formulation room

This is the heart of the production area. Here in the formulation room, employees call off all the raw materials needed and send them to the mixing machine. They manage the entire production process and monitor its progress on the computer screens. They can see precisely how many kilograms of which type of raw material is in which silo at any time, and what is happening in the mixing machine. They also have access to historical raw material data.

Bulk transportation

Bulk transportation

Tank trucks extract the calf milk powder from the storage silos and transport it to nearby veal farms. Before transportation can get underway, the laboratory first examines a final sample. Assuming everything is in order, the tank truck is allowed to depart. If there are any problems, the manufacturer withholds the consignment and that batch of dry calf milk is destroyed. The sample and the test results are archived for 9 months.

This is one example of how calf milk powder manufacturers do their bit to ensure the responsible and safe production of veal.

Transportation

Tank trucks transport the calf milk powder to storage silos on the veal farmer’s premises. The farmer then places the required quantity into the mixing machine where it is mixed with warm water before being fed to the calves.

This is the end of the tour feed production. Choose another link in the chain or use the red arrow on the right to navigate back to the floor plan.